Down Hole Sensor

Benefits, Features, Applications

Down Hole Sensor (DHS)

the ESP world leader

We supply simple and multi-sensor DHS guages. We offer the most up to date technology and topology, benefiting our Oil Company and Pump Company customers. All DOS products are designed and tested for rugged, desert and jungle on-shore applications, plus off-shore applications.

Product Reviews

We are a company committed to progressive technology enabling optimized reserves recovery. As technologists we know that cutting edge technology today is mainstream tomorrow and we are committed to high performance systems where they are required (deeper, hotter production) and cost effective technology at all times.

Our permanent gauge sensor product line standardizes where possible. The Surface Read Out can be used with all of our permanent gauges - TEC, ESP. Gauge carriers are the same on TEC and ESP completions (a standard gauge carrier is used at discharge on ESPs). Standard Tubing Encapsulated Cable (TEC) is used to connect together our gauges, even from the ESP gauge to the upper permanent gauge we use for discharge monitoring. A standard permanent gauge is used for discharge monitoring enabling pressure, temperature and vibration analysis at discharge for the first time on an ESP.

Well Considered Designs: At DOS you should always expect user friendly technology - simplified gauge test systems, Windows long file name file system, MMC/SD flash cards for years of data logging, Excel format logging files. USB and Portable Data Collector PDC) also available.

Field Service: Even though we have Service Engineers capable of assisting you we are committed to training and supporting you. DOS will go to your field to optimize support. Engineering Support Technology does not stand still. Technology within DOS does not stand still - it is the lifeblood of our company. Talk to us for all of your special needs.

DOS focuses on long term relationship with our clients to improve performance of your existing and new systems. DOS is a Canadian OEM manufacturer with an abundance of experience, both at head office and in the field. We deliver standard and custom engineered, high quality products to our customers. All DOS products are of rugged design for the intended environment; desert, jungle or arctic and off-shore applications.

About DOS Manufacturing

Our number one priority is testing. Every product designed, implemented, manufactured by DOS is thoroughly quality assurance tested by means of procedures developed over years of producing and receiving feedback from the customer in their field. We ask the customer, what do you like about this DOS product, and they let us know. Then we ask what they don't like about our product or what further features or changes they would like to see in the next production for them. DOS has recorded the field test results and they valuable answers from our customers to manicure the best systems in the world. We listen to our customers and when they see the next generation of the product, they see we carefully designed it for them.

All DOS manufactured produces meet the customer specifications. We usually exceed the specifications with proven features and quality control designs which we have carefully engineered with valuable assets learned from the 43 countries and hundreds of oil fields that DOS has worked.

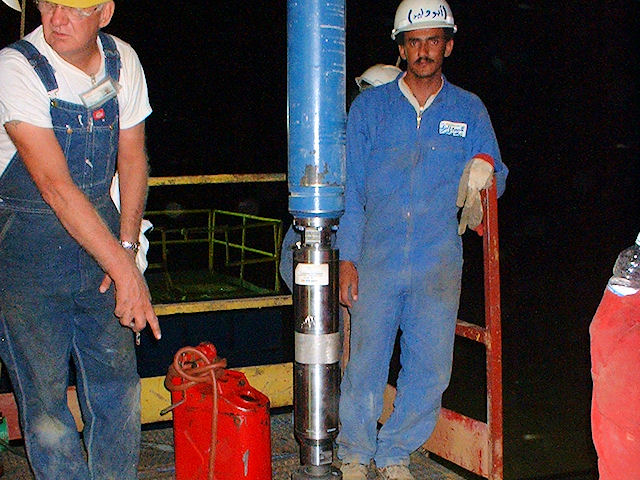

See our team in action |1:22 min|

Some of our Projects

...hover to view!

Short bio about DOS Manufactured Products

DOS Manufacturing starting with the 6-pulse VSD with PWM Sine wave filtered output back in 1996. Then we added the passive input filter to this VSD input and manufactured these for many years with good results but with limitations.

As newer VSD technology surfaced and as per oil company specifications, we developed the 12-pulse and 24-pulse VSD and also found limitations with additional drawbacks from the passive filter approach, such that we now require an additional expense phase shifting transformer and further finding restrictions on eliminating (mitigating) harmonics due to the unbalance and less then 100% VSD loading seen at most ESP oilfield.

Since 2013, we incorporated the Active Front End AFE-VSD with a customized harmonics elimination and power factor compensation input and with 3kHz output customized Sine wave filter. The AFE has the lowest input harmonic distortion, no matter how loaded and unbalanced, highest power factor, lowest losses, lowest operating cost, lowest per barrel cost and purest sine-wave input to the power source and output to the ESP motor.